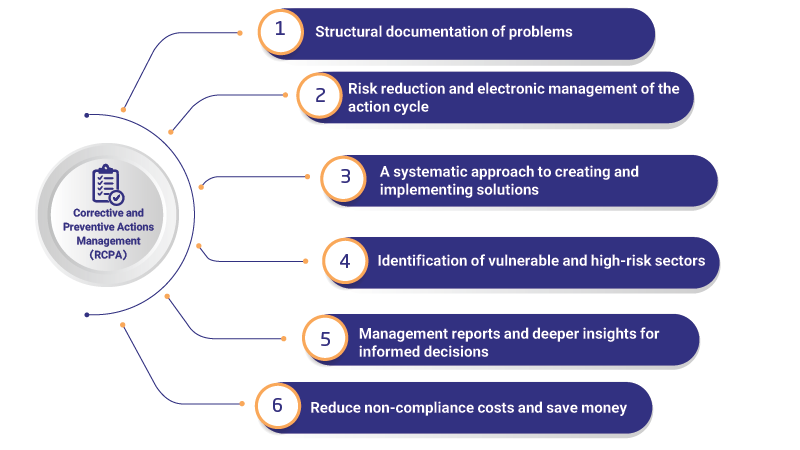

Corrective Actions/Preventive Action (RCPA)

Changes in industrial production always occur. Machine breakdowns, changes in delivery times, changes in material availability and priority orders happen every day in production. Production resource planning is part of a complex flow of information and decision-making that plans and controls production operations through the allocation of resources (raw materials, semi-finished products, personnel, machines, etc.) and determining the order of things necessary to produce products for delivery. It shapes the orders on time or bringing the production to the predetermined horizon and schedule. Optimal production planning requires regular, real-time reviews of production schedules to keep the plant operating at optimum performance. The Raybod orders and manufacturing planning module provides the planning unit with the tools and capabilities that provide the possibility of optimal use of available resources for timely delivery of customer orders or production according to the horizon and schedule. to give

Unsolved corrective/preventive actions can be costly and harmful

The simplicity and ease of use of the planner is the most important feature of Raybod orders and manufacturing planning software module as one of the subsystems of Raybod production management software. The important task of this module is manufacturing resource planning (MRP) and managing customer orders. This task involves defining work shifts, production lines, determining the capacity of machines, registering customer orders, defining the horizon and production schedule for the coming months and seasons, receiving raw material/semi-finished/finished product inventory from different warehouses, etc. It is very simple and efficient and with just a few clicks, while integrating the BOM and OPC of the goods, measuring the time of steps, the capacity of machines and work shifts, daily or periodic planning (for example, weekly or bi-weekly or monthly, etc.) gives The tools and capabilities in this software module intelligently enable the planning unit to make the factory more efficient and increase the reliability of order delivery

Features and facilities

Definition of the list of sources of identification of non-compliance and causes of occurrence

The possibility of registering an action request (corrective/preventive/improvement)

Initial evaluation of requests and approval and rejection of requests

The ability to manage approved requests, including holding an expert meeting/defining action steps and…

Special folder for unit managers, executives and follow-up experts

Report of requests to separate the process/identification origin/occurrence cause/issuing unit/receiving unit etc. in selected historical periods

save expense

Raybod Corrective Prevent Action audit software helps you save money on quality. Reduces time and effort spent on problem resolution by simplifying and automating corrective/preventive action processes. Effective root cause analysis, accurate corrective actions, and preventive actions lead to improved product quality, regulatory compliance, and customer satisfaction, resulting in significant cost savings.

Savings benefits:

Simplifying corrective and preventive measures, reducing manual efforts and administrative costs.

Identifying the root causes and implementing effective preventive measures to prevent problems.

Increase collaboration and accountability through simple workflow and automatic notifications.

Improving product quality, compliance with regulations, and customer satisfaction, reducing costs related to defects and non-compliance.

Providing accurate and up-to-date operational reports for informed decision-making and optimization of resource allocation