Product Warehouse Management (RPWM)

Changes in industrial production always occur. Machine breakdowns, changes in delivery times, changes in material availability and priority orders happen every day in production. Production resource planning is part of a complex flow of information and decision-making that plans and controls production operations through the allocation of resources (raw materials, semi-finished products, personnel, machines, etc.) and determining the order of things necessary to produce products for delivery. It shapes the orders on time or bringing the production to the predetermined horizon and schedule. Optimal production planning requires regular, real-time reviews of production schedules to keep the plant operating at optimum performance. The Raybod orders and manufacturing planning module provides the planning unit with the tools and capabilities that provide the possibility of optimal use of available resources for timely delivery of customer orders or production according to the horizon and schedule. to give

Product code and batch number in the storage of the final product

The simplicity and ease of use of the planner is the most important feature of Raybod orders and manufacturing planning software module as one of the subsystems of Raybod production management software. The important task of this module is manufacturing resource planning (MRP) and managing customer orders. This task involves defining work shifts, production lines, determining the capacity of machines, registering customer orders, defining the horizon and production schedule for the coming months and seasons, receiving raw material/semi-finished/finished product inventory from different warehouses, etc. It is very simple and efficient and with just a few clicks, while integrating the BOM and OPC of the goods, measuring the time of steps, the capacity of machines and work shifts, daily or periodic planning (for example, weekly or bi-weekly or monthly, etc.) gives The tools and capabilities in this software module intelligently enable the planning unit to make the factory more efficient and increase the reliability of order delivery

Features and facilities

The possibility of defining various warehouse slips (receipt, warehouse transfer, sales transfer, etc.)

Automatic registration of product receipt from the production department to the product warehouse

Ability to track products based on batch number/batch number/serial number

Various reports of final product production and shipments based on customer/destination

Possibility of advanced warehouse management based on Lot number or product code

save expense

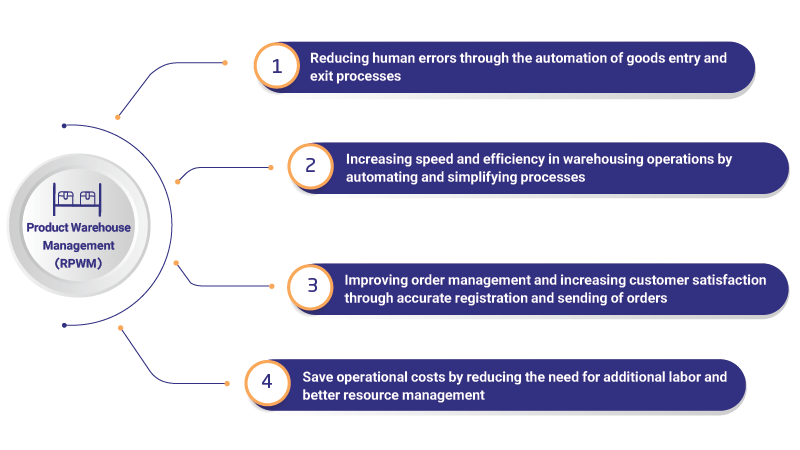

Using an RPWM warehouse management system can help save costs in several ways

Reduce human errors: Traditional, manual systems for recording and tracking goods can easily fall into error, which can lead to inappropriate inventory, incorrect orders and even additional costs for returning goods. By automating these processes, RPWM minimizes errors, thus reducing costs associated with errors.

Increasing the speed of processes: By automating the processes of registering and leaving goods, the time required to perform these activities is significantly reduced. This means increasing the efficiency of employees and reducing costs caused by low efficiency. As employees can focus more on more important tasks, operational costs are also reduced as a result.

Optimal management of orders and tracking: RPWM allows users to more accurately send and track orders and goods leaving the company. This not only helps to increase customer satisfaction, but also avoids costs caused by customer dissatisfaction and product returns, and helps to identify and track the final product.