Raybod-Nonconforming-Product (RNcP)

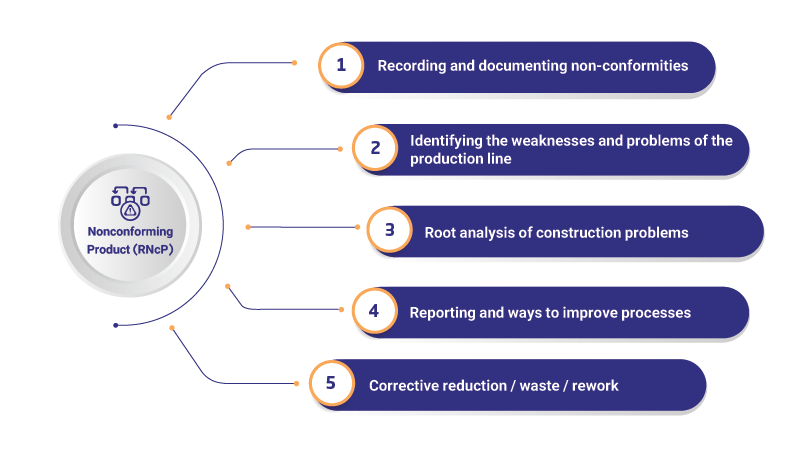

In the production process, maintaining the quality of products is always of particular importance. One of the key tools that helps to achieve this goal is the management of semi-finished/product non-conformities so that non-conformities detected in the quality control unit on the shipment can be controlled. The Raybod Nonconforming Product Management subsystem is a part of the production management and tracking software. This sub-system is designed to identify, manage and track any non-conformity and defects in production processes

Preventing the repetition of errors and increasing production efficiency

The non-conformance subsystem is an essential tool for any manufacturing organization that prioritizes product quality and customer satisfaction. By using this system, organizations will be able to quickly identify and correct any defects and non-conformities, which will ultimately lead to improved production processes and increased customer satisfaction.

Features and facilities

- Ability to define non-compliance coding

- The ability to determine the type of action for each manufacturing non-conformity

The possibility of defining the “description of non-conformance” template to increase the speed of existing controllers and requirements

- The possibility of reporting non-conformances that occurred in specific historical periods

- The possibility of reporting non-compliances of the operator/contractor of each stage

The possibility of viewing inconsistencies in cargo tracking in the production management system

The ability to register multiple codes at each stage of production and control

save expense

The manufacturing non-conformance subsystem has an important impact on reducing costs and saving money for organizations. Some of the main ways this system saves cost are

- Reducing waste of materials and products: By quickly identifying and correcting non-conformities, this subsystem helps to detect quality problems in time and prevent the production of defective products. This leads to the reduction of waste of raw materials and finished products.

- Prevention of remanufacturing: Early detection and correction of non-conformities in the early stages of production reduces costs related to remanufacturing. By avoiding the need to re-produce defective products, production costs and additional resources are reduced.

- Optimization of production processes: This system helps to identify weak points in production processes and provides improvement solutions. Optimizing these processes increases productivity and reduces work costs.

Reducing the costs of quality control: by using the manufacturing non-conformance subsystem, quality control operations are performed automatically and intelligently, which leads to a reduction in the need to hire human resources to perform these tasks. Also, the accuracy and efficiency of quality control increases.

- Reducing the costs of returning and repairing products: reducing the possibility of sending defective products to the market, the costs of returning and repairing products will be significantly reduced. This not only helps to reduce costs but also maintains and strengthens the brand’s reputation.

- Improved supply chain management: Accurate information and real-time updates under the manufacturing nonconformance system help improve supply chain management. This information allows companies to improve their sourcing and suppliers and reduce costs caused by delays and supply chain problems.

- Reduced costs related to dissatisfied customers: Higher quality of final products and reduction in the number of defective products will reduce the level of customer dissatisfaction and avoid the costs of customer complaints and the implementation of defective product returns.

- Considering that the costs that arise due to the production of defects, rework and quality problems can consume a major part of organizations’ budgets, the use of manufacturing non-conformance subsystem can have a significant impact on financial savings and increasing the overall productivity of organizations. .