Raybod Assembly Checklist Management(RACM)

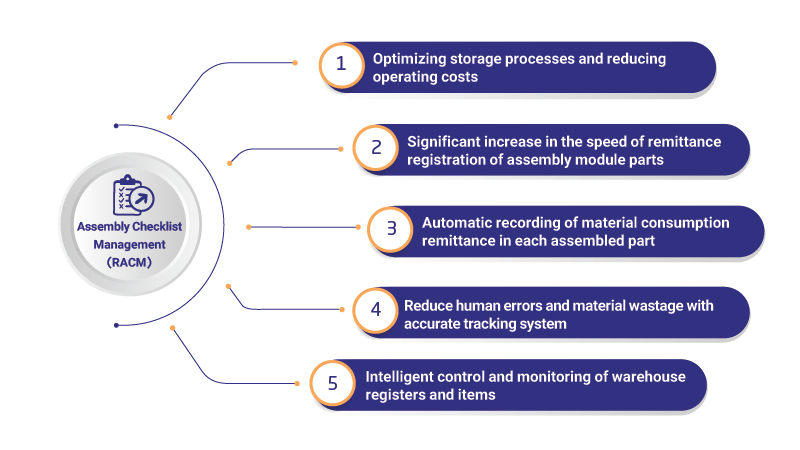

Raybod Assembly Checklist Management software is designed as an intelligent solution to optimize warehousing processes. This module is very efficient for companies that produce products with assembly parts, because like an intelligent assistant, it helps the warehouse keeper, systematically and based on the BOM, sends and receives the items required for the production of a semi-assembled assembly, which at the same time Increasing the speed of registration and reducing the error of parts delivery also helps transparency and accurate tracking of parts

Preventing registration mistakes and increasing registration speed

Ribbed Assembly Checklist Management (RACM) software effectively optimizes the process of sending and receiving production items for assembly parts by providing an intelligent solution to warehouse keepers. By combining the list of materials (BOM) and accurate identification of items, this software module minimizes the possibility of human error and increases the speed and accuracy of warehousing operations and helps the storekeeper as a reliable assistant in moving goods. In simpler terms, the assembly checklist management software module (RACM) as one of the sub-systems of the comprehensive production management software of Raibad, not only provides capabilities to the warehouse keeper that, with high speed and accuracy, the items that must go through It is easy to hand over a bill to the assembly operator and spend it when receiving the assembly part, but with the ability to track and identify the parts, it also plays a significant role in improving inventory management and reducing production costs

Features and facilities

Record the checklist of parts required for the assembly of the semi-finished product/product

The possibility of registering and managing requests for parts, before the delivery date for collection from the warehouse

The possibility of making notes for fractional items

The possibility of registering parts of the checklist at once in the shipment

The possibility of receiving a part of the assembled semi-finished product in proportion to the delivered parts

save expense

Using Ribbed Assembly Checklist Management (RACM) software can help save costs in several different waysReducing errors: by automating the process of identifying and categorizing items based on the BOM, the possibility of human errors is reduced. This can prevent costly mistakes in the later stages of production and storage

Reducing waste: With accurate tracking and proper warehouse management, the possibility of losses due to spoilage, expiration or unnecessary accumulation of goods is reduced. This helps to reduce the waste of materials and parts

Optimizing the use of resources: improving the management and allocation of resources to different production and warehouse departments, increases efficiency and productivity, which can help reduce operational costs

Increased speed and productivity: By increasing the speed in responding to production needs and reducing the time wasted in finding and managing items, production time is reduced and labor costs and production stoppages are reduced.

Transparency and improved decision-making: Access to accurate and up-to-date information about warehouse inventory helps management make better decisions about purchasing and using materials, which leads to reduced purchasing costs and avoids unnecessary purchases. All these factors together lead to a reduction in overall costs and an increase in profitability for the organization